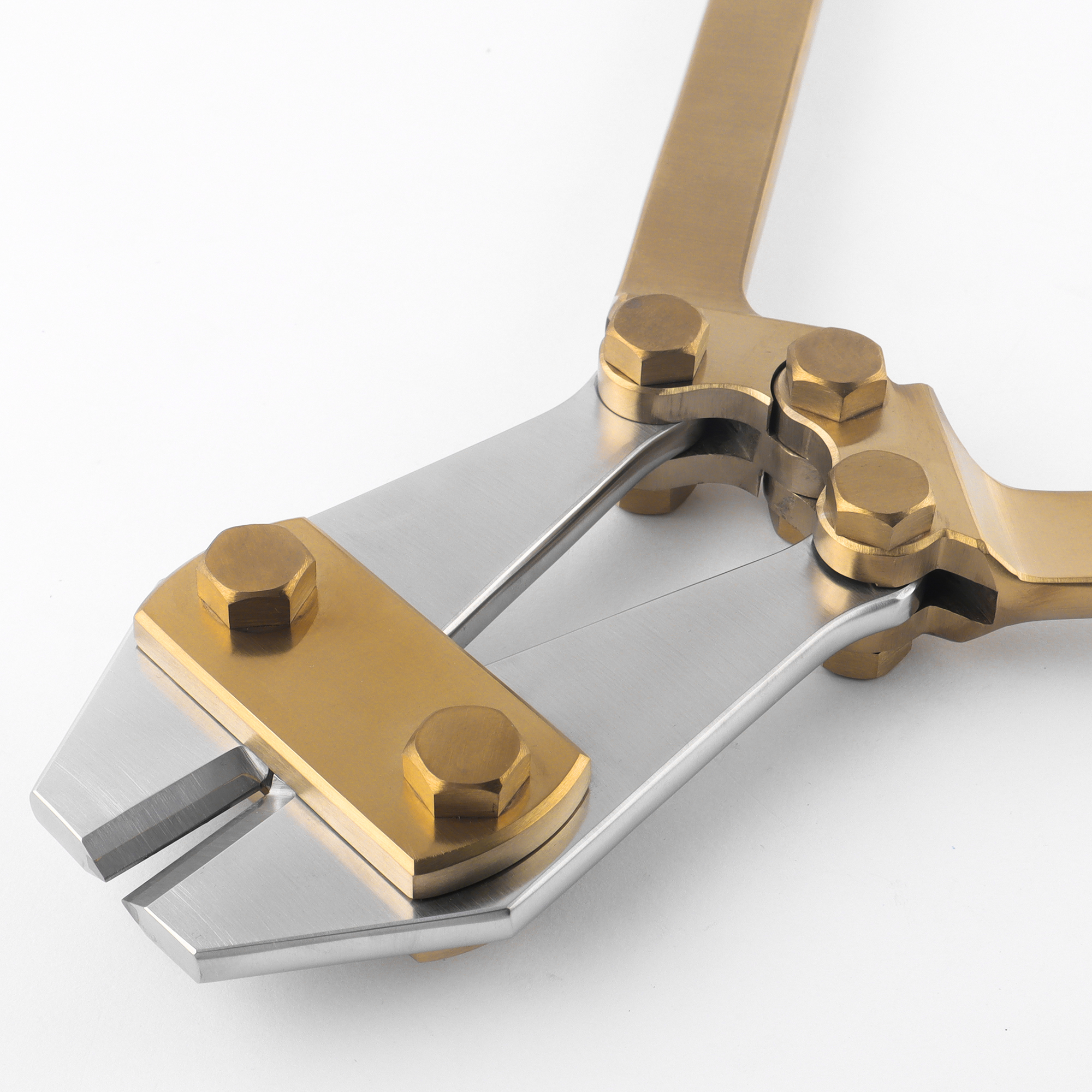

Bone Cutter

The bone cutter, also known as an osteotome, is a surgical instrument used to cut and shape bones during orthopedic and maxillofacial surgeries. It is typically used to section or fragment bones, allowing for better exposure of the surrounding tissue or the reattachment of fractured bones. The bone cutter has a sharp, curved or angled blade that is designed to minimize damage to surrounding soft tissue while effectively cutting through bone. During surgery, the instrument is typically held firmly by the surgeon and applied with a gentle, controlled motion to carefully section the bone. The bone cutter is often used in conjunction with other instruments, such as chisels and saws, to achieve the desired outcome. Its precise control and versatility make it an essential tool for many orthopedic and maxillofacial procedures, including joint replacements, fracture repairs, and dental implant surgeries.

Description

Bone cutter instruments, also known as osteotomes, are specialized surgical instruments used to cut and shape bone in various medical procedures. In the manufacturing process, the production of bone cutter instruments involves a combination of materials science, design, and craftsmanship. The process begins with the selection of high-quality raw materials, such as stainless steel or titanium, which are then carefully machined and shaped to create the desired form and function.

The manufacturing process involves multiple stages, including design, prototyping, testing, and quality control. Designers work closely with surgeons and other medical professionals to create instruments that meet specific requirements and specifications. Prototypes are then created and tested to ensure that they meet the required standards for precision, durability, and performance. Once the design is finalized, the instruments are manufactured through a combination of machining, grinding, and polishing techniques to achieve the desired surface finish and accuracy.

In addition to traditional manufacturing methods, some bone cutter instrument manufacturers are incorporating advanced technologies such as 3D printing and laser cutting to improve the production process. These technologies allow for increased precision, reduced waste, and faster production times. Quality control is also a critical aspect of bone cutter instrument manufacturing, with rigorous testing and inspection procedures in place to ensure that each instrument meets the highest standards of quality and performance. As a result, bone cutter instruments are designed to provide precise cutting and shaping of bone tissue while minimizing damage to surrounding soft tissue.

Reviews

There are no reviews yet.