Welcome to WHC Supplies..

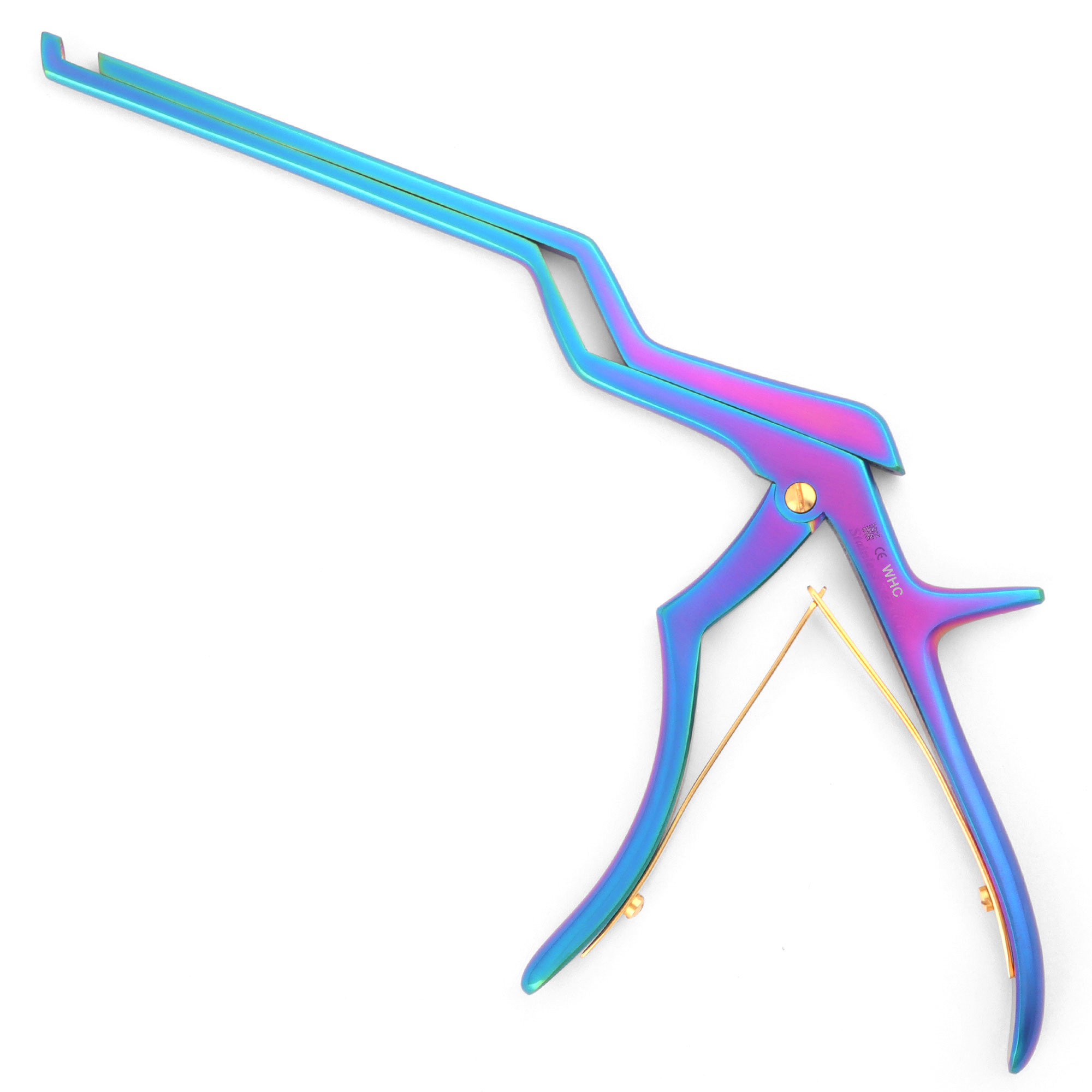

At WHC SUPPLIES, we take pride in being a leading manufacturer of high-quality surgical dental instruments. Our commitment to excellence is evident in every instrument we produce, from the design to the final product. Our team of experienced professionals, including skilled craftsmen and engineers, work together to ensure that each instrument meets the highest standards of quality and performance.

Our product range includes a vast array of surgical dental instruments, including scalpels, bone cutters, curettes, and more. Each instrument is designed with precision and care, taking into account the unique needs of dental professionals and patients alike. Our instruments are made from the finest materials, carefully selected for their durability, strength, and corrosion resistance.

Featured Products

-

Add to WishlistAdd to Wishlist

-

Add to WishlistAdd to Wishlist

-

Add to WishlistAdd to Wishlist

-

Add to WishlistAdd to Wishlist

-

Add to WishlistAdd to Wishlist

-

Add to WishlistAdd to Wishlist

-

Add to WishlistAdd to Wishlist

-

Add to WishlistAdd to Wishlist

PRODUCTION PROCESS

The manufacturing process of surgical instruments involves a combination of traditional craftsmanship and modern technology. The process typically begins with the selection of high-quality materials, such as stainless steel, titanium, or other durable alloys. The chosen materials are then cut and shaped into the desired form using various techniques, including machining, grinding, and polishing. This stage requires great attention to detail to ensure that the instruments meet the required specifications and tolerances.

The next stage involves the assembly of the instrument’s components, such as handles, shafts, and tips. This may involve welding, soldering, or other bonding techniques to create a strong and durable joint. The assembly process is critical to the instrument’s overall performance and requires precision and attention to detail to ensure that all parts fit together seamlessly. Once assembled, the instruments are then subjected to rigorous testing and quality control measures to ensure that they meet the required standards.

The final stage of the manufacturing process involves sterilization and packaging. The instruments are cleaned and disinfected using specialized methods, such as autoclaving or chemical sterilization, to ensure that they are free from bacteria and other contaminants. They are then packaged in sterile wrappers or cases and ready for use in operating rooms. Throughout the manufacturing process, manufacturers must adhere to strict quality control measures to ensure that their instruments meet the highest standards of quality, safety, and performance. This includes regular inspections, testing, and certification by regulatory bodies to ensure that the instruments meet international standards.